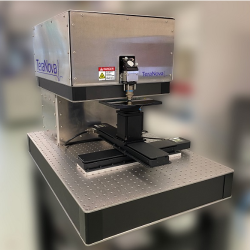

JL-300SCG - HIGH PRECISION WAFER GRINDING MACHINE

Model: JL-300SCG

Category: Semiconductor Smart Auto Solution

Exhibitor: JOEN LIH MACHINERY CO., LTD.

Booth No: N308

Characteristic

1. APPLICATIONS

A wafer grinding machine essentially operates based a vertical grinding machine, with a diamond grinding wheel securely integrated into an (aerostatic)air-bearing spindle. In semiconductor manufacturing, where extremely high precision and flatness are required for hard and brittle materials, the diamond grinding wheel is used to thin and grind the wafer, which is held in place on an (aerostatic) air-bearing worktable. This process ensures that the wafer meets the strict flatness and surface roughness standards required in wafer fabrication.

2. MATERIALS

A wafer grinding machine is specifically designed for precision grinding operations on wafers, ceramics, quartz, glass, aluminum natria, gemstones, and similar materials etc.

3. FEATURES

Built-in motor (aerostatic) air-bearing spindle. The spindle rotation accuracy can reach 0.1 µm. The air-bearing rotary worktable meets strict grinding precision requirements, with a rotational accuracy of up to 0.1 µm. The Z-axis feed resolution is 0.01 μm.

4. STANDARDEQUIPMENT

- Diamond grinding wheel Flange

- Ceramic vacuum suction table

- Spindle temperature controller

- Vacuum pump

- Tool box with tool kits

5. OPTIONAL EQUIPMENT

- Thickness Measurement

- Auto loading and uploading

Other Products

Products you may be interested in

Highest Rated Products