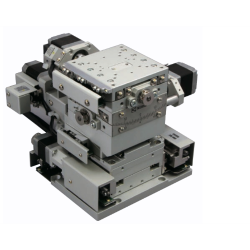

Position Comparison and Trigger

Model: 207-C344F

Category: Electronic Equipment Key Module & Parts

Exhibitor: TAIWAN PULSE MOTION CO., LTD.

Booth No: M536

Characteristic

EtherCAT Position Detection and Monitoring:

*Real-Time Position Tracking: These modules can continuously monitor and track the position of a moving part (e.g., robotic arm, conveyor belt, or valve).

*High Precision: It provides accurate position readings (e.g., in millimeters or degrees), crucial for high-precision tasks in automation.

*Feedback Systems: They often use sensors (like encoders, linear scales, or potentiometers) to provide feedback on the current position, ensuring the system is where it should be.

Triggering Mechanism:

It supports multiple trigger conditions such as Auto trigger, Table trigger, and Toggle rigger modes, for example, when the system reaches a specific position, or when a certain position is surpassed.

Application

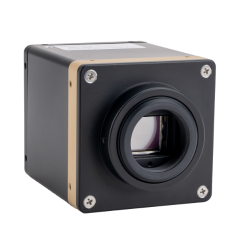

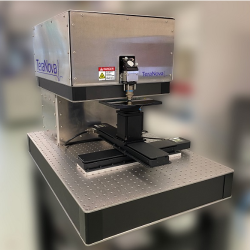

Camera Positioning for Inspection or Monitoring:

In automated inspection systems (e.g., quality control on production lines), cameras are often mounted on robotic arms or movable platforms.

Position comparison can ensure that the camera is in the correct location for capturing high-quality images at precise angles.

Automated Camera Positioning: Cameras can be mounted on robotic arms or other adjustable platforms. The position comparison module can track the camera’s location and ensure it reaches predefined setpoints, ensuring the camera is positioned exactly where needed to capture images from specific angles.

Setpoint and Triggering: The system can trigger the camera to start recording or capturing images when the camera reaches a specific position. For example, when the camera reaches the target position above a production line, it automatically starts recording, ensuring that the correct component is being monitored.

Other Products

Products you may be interested in

Highest Rated Products